Is the rolling machine mechanically or hydraulically driven?

2024-05-20The rolling machine has a history of using mechanical transmission for decades. Due to its simple structure, reliable performance, and low cost, it is still widely used in small and medium-sized rolling machines. On low-speed and high torque plate rolling machines, hydraulic transmission is increasingly used due to the large volume of the transmission system, high motor power, and significant fluctuations in the power grid during startup.

In recent years, there have been plate rolling machines that use hydraulic motors as the source to control the movement of working silver, but the main drive is still mechanical transmission. There are also fully hydraulic plate rolling machines that use hydraulic motors as the power source for the rotation of working rollers.

The machine tool factory specializes in producing plate rolling machines, cone rolling machines, flatbed machines, and leveling lines, ensuring quality and low prices.

1. Three roll plate rolling machine: including symmetrical three roll plate rolling machine, asymmetric three roll plate rolling machine, horizontal downward adjustment three roll plate rolling machine, inclined downward adjustment three roll plate rolling machine, curved downward adjustment three roll plate rolling machine, and vertical downward adjustment three roll plate rolling machine.

2. Four roll plate rolling machine: divided into side roll tilt adjustment four roll plate rolling machine and side silver arc adjustment four roll plate rolling machine.

3. Special purpose plate rolling machines: including vertical plate rolling machines, marine plate rolling machines, double roll plate rolling machines, cone plate rolling machines, multi roll plate rolling machines, and multi-purpose plate rolling machines. Chengxiang Forging Machine Tool Factory in Guoli Town, Huantai County specializes in the production of plate rolling machines, cone rolling machines, flat machines, and leveling lines, with quality assurance. We are also a professional second-hand plate rolling machine with low prices.

2、 Introduction to the characteristics of hydraulic three roll plate rolling machine

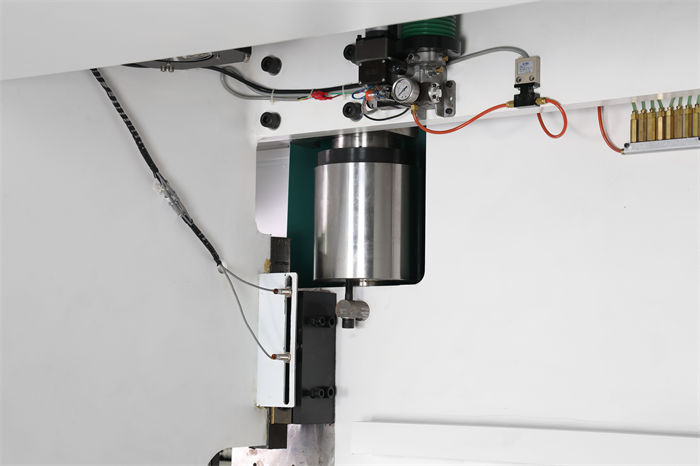

1. The upper roller of the hydraulic three roll plate rolling machine can be vertically lifted and lowered. The hydraulic transmission for vertical lifting is obtained by the hydraulic oil in the hydraulic cylinder acting on the piston rod, and the lower roller is driven by rotation. The gear mesh is output by the reducer to provide torque for the plate. The lower roller has a support roller at the bottom and can be adjusted. The upper roller is in a drum shape, improving the straightness of the product. It is suitable for tanks with various cross-sectional shapes of ultra long specifications.

2. The wave pressure three roll plate rolling machine is an upward adjustment symmetrical three roll plate rolling machine, which can roll metal plates into circular, arc-shaped, and conical workpieces within a certain range. The two lower rollers of this machine are active rollers, and the upper roller is driven roller. It is widely used in shipbuilding, boilers, aviation, hydropower, chemical, metal structure, and mechanical manufacturing industries.

3. The hydraulic three roll plate rolling machine is suitable for bending deformation of metal sheets. It can roll circular, arc-shaped, and conical workpieces within a certain range, and has a pre bending function at the end of the sheet. The two lower rollers of this model are active rollers that can move horizontally, while the upper roller is driven roller that can move up and down. The movement methods are mechanical and hydraulic, and the transmission shaft is connected by a universal joint.